Flowmeter Solution

1) The Fundamentals of Flow Measurement

Flowmeters are essential instruments designed to measure the rate at which a fluid (liquid or gas) passes through a specific point in a system, typically a pipe or channel. They quantify flow as either volumetric rate (like cubic meters per hour or gallons per minute) or mass flow rate. Accurate flow data is crucial across countless industries for effective process monitoring, precise control, operational optimization, and resource management.

2) Understanding Ultrasonic Flowmeters

These meters typically operate using the “Transit-Time” principle. They employ pairs of transducers mounted on the pipe wall, sending ultrasonic sound pulses diagonally across the flow stream – one pulse traveling downstream and another upstream. Because the pulse moving with the flow travels faster than the one moving against it, there’s a measurable time difference. This time difference is directly proportional to the average velocity of the fluid. Combined with the pipe’s cross-sectional area, this allows for accurate calculation of the volumetric flow rate. A key advantage is the potential for non-invasive “Clamp-On” installation.

3) Understanding Electromagnetic Flowmeters (Magmeters)

Electromagnetic flowmeters, or magmeters, function based on Faraday’s Law of Electromagnetic Induction. Coils generate a magnetic field perpendicular to the flow direction within a pipe section. When an electrically conductive fluid moves through this magnetic field, it acts as a conductor, inducing a voltage across electrodes positioned in the meter wall. This induced voltage is directly proportional to the average velocity of the fluid. Crucially, this technology requires the fluid being measured to have a minimum level of electrical conductivity, making it unsuitable for hydrocarbons, gases, or very pure water.

4) Why Measuring Flow is Critical

Accurate flow measurement is indispensable for numerous reasons:

- Process Control: Enables precise control over mixing, batching, and dosing operations in manufacturing.

- Custody Transfer & Billing: Ensures fair trade when buying or selling fluids like water, fuel, or chemicals.

- Efficiency & Optimization: Helps monitor and reduce energy consumption (e.g., heating/cooling systems) and water usage, leading to cost savings.

- Safety & Compliance: Facilitates leak detection in pipelines and ensures adherence to environmental discharge regulations.

- Quality Control: Guarantees product consistency by verifying correct ingredient proportions and process parameters.

5) Addressing Key Measurement Challenges

Ultrasonic and Electromagnetic flowmeters are frequently selected because they effectively address common challenges and modern requirements, offering benefits like high reliability due to no moving parts, excellent accuracy, low maintenance needs, and minimal impact on the process (no pressure drop). They are also versatile for handling various fluids and installation conditions.

6) Advantages of Ultrasonic and electromagnetic Flowmeters

Non-Invasive Installation: Unique “Clamp-On” capability allows installation entirely from outside the pipe, avoiding costly pipe cutting and process shutdowns, perfect for retrofits or hygienic needs.

Large Pipe Economy: Often the most cost-effective solution for measuring flow in very large diameter pipes.

Broader Fluid Compatibility: Can measure non-conductive liquids (like oils or pure water) where electromagnetic meters cannot (performance depends on fluid acoustics).

High Reliability & Low Maintenance: Both technologies typically feature no moving parts, drastically reducing wear, tear, and routine maintenance requirements compared to mechanical meters.

Energy Efficient (No Pressure Drop): Their design is generally obstructionless, meaning they don’t impede flow or cause pressure loss in the pipe, saving pumping energy.

Wide Flow Range Capability: Accurately measure a broad spectrum of flow rates, from very low to very high (high turndown ratio).

Bi-Directional Measurement: Inherently capable of measuring flow accurately in both forward and reverse directions.

7) Selecting the Right Flowmeter

Ultrasonic and Electromagnetic flowmeters are powerful, reliable technologies addressing many modern flow measurement needs. Ultrasonic meters offer unique non-invasive capabilities and large pipe suitability, while electromagnetic meters provide high accuracy for conductive liquids. Understanding the operating principles, advantages, and typical specifications of each type is crucial for selecting the most appropriate and cost-effective solution for any given application. Careful consideration of the fluid properties, required accuracy, installation constraints, and data needs will guide the best choice.

8) Introducing the MF300 Series Electromagnetic Flowmeters: Versatile Solutions for Diverse Industries

The MF300 Series offers a versatile solution with customizable connections and a wide size range (25mm – 1400mm). These electromagnetic flowmeters typically provide an accuracy of ±0.5% and can handle fluids with a minimum conductivity of 5 µS/cm. Depending on the liner material selected, they can operate across a broad temperature range, and standard models support pressure ratings up to PN40. With various output signals and robust IP67/68 protection, the MF300 Series ensures reliable performance in diverse applications, from Water/Wastewater to Food/Sanitary and large-scale infrastructure projects.

9) Introducing Our Comprehensive Range of Ultrasonic Flowmeter Solutions: Precision, Versatility, and Intelligence

Our Ultrasonic Flowmeters represent a cutting-edge solution for accurate and reliable flow measurement across a vast spectrum of industrial applications. Leveraging advanced ultrasonic technology, these flowmeters offer significant advantages, including non-intrusive measurement options, a wide operational range, and intelligent features designed for optimal performance and data management.

At the heart of our ultrasonic flowmeter technology lies advanced multi-pulse processing, ensuring stable and dependable readings with an impressive accuracy better than ±1%. This robust technology minimizes the impact of fluid disturbances and enhances measurement reliability, providing you with confidence in your flow data.

We recognize the diverse installation requirements across different industries. To address this, our Ultrasonic Flowmeters are available in three flexible installation configurations:

Clamp-on: This non-invasive method allows for quick and easy installation without the need to cut into the pipeline, minimizing downtime and offering a cost-effective solution for temporary or permanent flow monitoring.

Insertion: Ideal for larger pipe diameters, insertion flowmeters provide a cost-efficient way to measure flow by inserting sensors into the flow stream.

Wetted/Inline: For applications demanding the highest level of accuracy and direct fluid contact, our wetted/inline models offer a traditional yet highly reliable measurement solution.

Our Ultrasonic Flowmeters are engineered to accommodate an exceptionally wide range of pipe sizes, from DN15mm to DN6000mm. This extensive compatibility makes them suitable for applications ranging from small process lines to large-scale water distribution networks, oil and gas pipelines, and HVAC systems.

Beyond accurate flow measurement, our Ultrasonic Flowmeters are equipped with powerful features for enhanced operational insight. The built-in data logging capability allows for comprehensive recording and analysis of flow data, enabling trend monitoring, historical analysis, and informed decision-making. Seamless integration with existing control and monitoring systems is facilitated through the RS485 communication interface, enabling easy networking and data exchange.

Embracing the need for remote monitoring and accessibility, our Ultrasonic Flowmeters are GPRS module ready, allowing for convenient and cost-effective wireless data transmission. This feature enables real-time flow monitoring and data access from virtually anywhere.

Furthermore, our Ultrasonic Flowmeters offer more than just flow measurement. With the addition of temperature sensors, they become Heat/Energy Measurement capable, providing a comprehensive solution for monitoring thermal energy consumption and efficiency in heating and cooling applications.

By offering a combination of high accuracy, flexible installation options, wide pipe size compatibility, intelligent data management, and energy monitoring capabilities, our Ultrasonic Flowmeters provide a versatile and powerful solution for a multitude of flow measurement challenges.

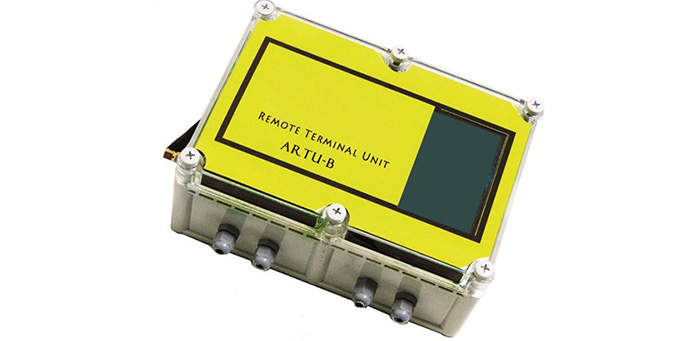

10) Our Intelligent Instrumentation & Systems for Enhanced Flow Management

To ensure seamless operation, comprehensive data management, and remote accessibility for our flowmeter solutions, we offer a powerful suite of instrumentation and systems. These components are designed for robust field deployment and user-friendly interaction.

The integrated Touchscreen Interface provides a convenient and intuitive platform for on-site configuration, setup, and real-time data viewing, empowering technicians with immediate access to critical information and control parameters.

Built for demanding environments, our instrumentation features a robust IP67 rated enclosure, ensuring reliable performance even in challenging field conditions with protection against dust and water ingress.

Versatile connectivity is a cornerstone of our system. It offers flexible sensor/instrument connection via both RS485 and 4-20mA inputs, allowing for seamless integration with our range of flowmeters and other compatible devices.

For secure and reliable data storage, our instrumentation incorporates reliable SD Card Logging, capturing crucial data, error logs, and alarm events. Data retrieval is straightforward and efficient via the integrated USB Port.

Embracing the power of remote communication, our system features GSM/GPRS transmission capabilities, enabling seamless data transfer to a central Telemetry Website. This allows for remote monitoring, analysis, and management of your flowmeter installations. Furthermore, for critical alerts and backup communication, an automatic SMS backup channel ensures that vital information is always accessible.

Our intelligent system includes smart SIM management features for efficient and cost-effective cellular communication, along with comprehensive user access control to maintain system security and prevent unauthorized modifications.

Powering this advanced instrumentation is a standard 9-25V DC power supply, ensuring compatibility with common industrial power sources.

By integrating these intelligent instrumentation and system features with our advanced flowmeter technology, we provide a complete and powerful solution for flow measurement, data management, and remote monitoring, giving you unparalleled control and insight into your processes.