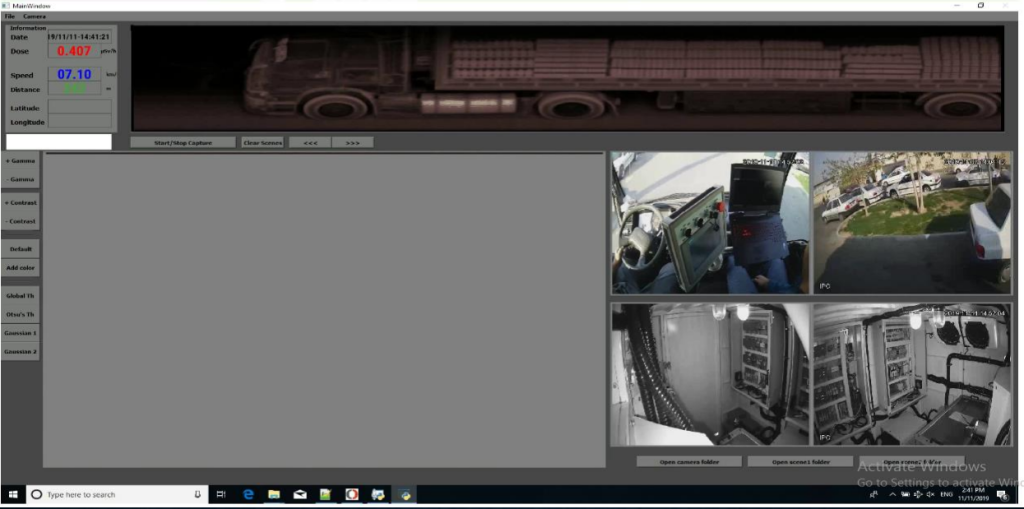

Mobile Inspection System

Mobile Inspection System: Backscattered X-rays

introduction

Mobile Backscatter X-ray Inspection Systems provide a fast, nonintrusive way to detect hidden threats like explosives, weapons, and

drugs. Designed for use in areas without fixed inspection setups — like

borders, ports, or events— they combine advanced X-ray imaging with

the mobility of a van or truck to handle large items like vehicles and

cargo efficiently.

The Technology: How Backscatter Works

Backscatter X-ray technology differs from traditional X-ray systems by detecting radiation that reflects back from an object rather than passing through it. It uses low-dose X-rays, which scatter more from lighter, organic materials and less from denser materials like metals. By

measuring the intensity of the scattered radiation point-by-point, the

system creates images that highlight hidden organic substances and

anomalies.

Backscatter X-ray Technology : Key Advantages

One-Sided Imaging: Because the X-ray source and detectors are

positioned on the same side of the object, the system can perform

inspections even when access to the opposite side is impractical or

impossible. This is invaluable for scanning the sides and roofs of

vehicles, cargo containers stacked or positioned against walls, and even

building structures.

Backscatter X-ray Technology : Key Advantages

Mobility and Flexibility: Integrated onto a vehicle, the entire system can

be rapidly deployed to virtually any location. This mobility brings

advanced inspection capabilities to temporary checkpoints, remote

areas, or dynamically changing security perimeters, reducing reliance on

costly fixed infrastructure and increasing operational tempo.

Backscatter X-ray Technology : Key Advantages

Enhanced Material Detection: Backscatter systems excel at detecting

low-density organic materials that might be missed by other inspection

methods. Their sensitivity makes them highly effective for identifying

hidden explosives (bulk, sheet, or liquid), narcotics, large amounts of

currency, plastic weaponry, and even stowaways concealed within

vehicles or cargo. This capability often complements traditional

transmission X-ray systems, which are typically better at imaging dense

metallic objects.

Backscatter X-ray Technology : Applications

Border Security: Screening vehicles and cargo for contraband, weapons, and

undocumented individuals.

Ports and Cargo Facilities: Inspecting shipping containers and freight nonintrusively.

Event Security: Securing large public gatherings by scanning incoming

vehicles, equipment, and deliveries.

Critical Infrastructure Protection: Monitoring vehicles entering sensitive sites

like power plants or government buildings.

Law Enforcement: Providing support for searches and investigations requiring

non-destructive examination.

Backscatter X-ray Technology : Safety

While utilizing X-ray technology, these systems are designed with safety as a

priority. They employ low doses of radiation and incorporate integrated

shielding and clearly defined safety zones to protect both operators and the

public. Operators receive specific training in radiation safety protocols, and the

systems adhere to strict international safety standards

Backscatter X-ray Technology : Standards

| X-Ray Source Standards | Technical Standards | Applications |

|---|---|---|

| ASTM F1039; W2002 (21CFR 1020.40) | ANSI N42.44-2008 ASTM F792 – 2008 | Vehicle / Human Checkpoints |

| ASTM F1039; W2002 (21CFR 1020.40) | ANSI N42.45 – 2011 | CT / EDS |

| ANSI N43.16 – Draft IEC 62523 – 2010 ANSI N43.14 – 2011 | ANSI N42.46 – 2008 ANSI N42.41 – 2007 IEC 62523 – 2010 | Cargo Checkpoints |

| ANSI / HPS N43.17 – 2009 ANSI / ANS 6.1.1 – 1991 IEC 62463 – 2010 | ANSI N 42.47 – 2010 IEC 62709 – CD1 | Full Body Scanning |

| ANSI / HPS N43.3 – 2008 | NIJ 0603.01 ANSI N42.55 – Draft | Bomb Disposal Unit |

Backscatter X-ray Technology : Product Specification

| Technical Specification | |

|---|---|

| Total Input Power | 16KVA |

| X-Ray Tube Voltage | 1225KV |

| Duty Cycle | 100% |

| Scanning Speed | 1- 10 Km/h |

| Working Temperature | -20 – 70 c |

| Working Humidity | 10 – 98% |

| Equivalent Dose (Per Scan) | < 10 μSv |

| Absorbed Dose (Inside Cabin) | < 0.5 μSv / h |

| Absorbed Dose (Outside Cabin) | < 0.1 μSv / h |

| Image Resolution | 1.0 cm |

| Relative Penetration Depth (Compared to Steel) | 6.0 mm |

| Cooling Technology | Closed Recirculated Cooling System |

Backscatter X-ray Technology : Case Studies

Backscatter X-ray Technology : Case Studies